Page updated: 17 November 2016

Mast

Mast

The SeaHawk's standard mast stands approximately 21ft above the gunwale. Although there is a report, mentioned on the History page, of two boats having been built with 24ft masts.

One of these taller masted boats was prepared for the 1992 Boat Show, but that one appears to have been delivered to its first owner with a standard height mast. Apart from the customer's name, nothing more is known of the other boat.

There is some evidence that the main suppliers of masts changed between Reedcraft and Moore's produced boats. Described here are the two most popular kinds fitted by each of the main builders.

Reedcraft

Reedcraft

The earliest SeaHawks rig was supported on a black anodised aluminium mast and boom, with stainless steel standing rigging. The black finish was quickly dropped. For most, if not all of Reedcraft production, spars were by the now defunct company SSS.

The company badge can be found on the front of these masts just below the cleat for securing the topping lift. On this mast the channel to take the gooseneck slide is riveted on to the back of the mast. The gooseneck fitting, by Gibb Proctor, is permanently, though loosely fixed to the boom, to allow it to turn for reefing.

Unlike the topping lift, seen above, the halyards run inside the mast and emerge from two side-by-side pulleys.

On boats without tabernacles, the mast is stepped on an aluminium alloy plate mounted on the cabin roof. On many Broads based craft the mast is supported in a tabernacle that makes lowering and raising the mast, for passing under bridges, significantly easier. The most popular design of tabernacle is illustrated in the Moore's section below.

The next significant feature above the gooseneck are the spreaders and anchorage for the lower, forward, shrouds. The spreaders themselves are a hollow alloy pole secured to the fitting on the mast with a split pin. The upper shroud passes through a casting, also secured with a split pin, although, over time, this effectively welds itself to the spreader tube.

Above the spreaders the aft (upper) shrouds are fixed to the mast at the point where the jib halyard emerges and the forestay is attached.

At the top of the mast an eye takes the topping lift and on the saboard side a small hole in the masthead casting provides a point through which to thread the burgee halyard.

Moore & Sons

Moore & Sons

The most common mast found on a Moore's built boat is manufactured by Holt Allen and their logo can be seen on the example below.

The gooseneck arrangement is significantly different from the SSS design found on most Reedcraft boats. Rather than being permanently attached to the boom it is attached to the mast where rather than use a special track, it uses the same slot in which the clips on the sail run.

This approach means that the boom is not "attached" to the mast but rather held in place by a combination of the tension in the kicking strap, halyard and wind in the sails.

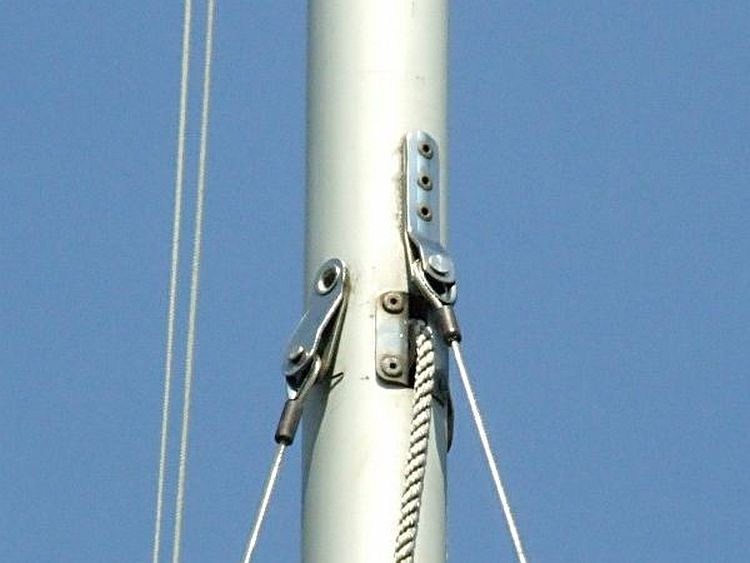

The tabernacles seen above are the most common form found on any SeaHawk. It is not known whether those found on earlier Reedcraft boats were retro-fitted rather than being fitted when new. But even these are not identical. You'll notice a subtle difference between the two. One has a shackle secured at the base to which to attach the kicking strap, whereas the other lacks this and the kicking strap is secured to the bar part way up the tabernacle.

If you have photographs and other details of the spreaders, hounds and top of this type of mast please post them on the Forum.

Boom

Boom

Reedcraft

Reedcraft

Apart from the very early SeaHawks, which had black anodised spars, those with sail numbers up to the high two hundreds, at least, use this boom, which is part of the spars supplied by SSS.

The swivel at the aft end allows for simple roller reefing. Seen above is an original double block as supplied with the boat when new.

The socket for the kicking strap is of a simple key-hole pattern.

The gooseneck fitting is permanently anchored inside the casting at the end of the boom. The deepest part of the fitting is rounded and once pulled out as far as it will go can be rotated to allow for roller reefing. The outer 1.5cm, however, is square in cross-section and fits snugly into the hole so locks the boom with the required number of turns.

Moore & Sons

Moore & Sons

The Holt Allen gear from a late Moore's boat looks remarkably similar to that found most commonly on almost all Reedcraft boats..

As does the keyhole socket for the kicking Strap found on the same boom.

Jib Sheet Cleats

and Winches

Jib Sheet Cleats

and Winches

The sheets for the standard jib pass through both cabin roof and aft corner fairleads before being taken to a cleat or winch. The genoa is sufficiently big that the sheets have to be taken outside of the shrouds and direct to the cabin corner fairlead, making the cabin roof fairleads redundant.

Reedcraft

Reedcraft

Reedcraft boats all came with jam cleats mounted on wooden blocks on either side of the cabin door. The wooden spacer is required to raise the cleat higher than the lip around the cabin door. The sheet can then be made to fall between the jaws of the cleat simply by pulling the sheet tight across the open cabin doorway. Without the spacer either the crew suffers skinned knuckles or a second hand is required to push rope into the cleat.

The disadvantage of this design only shows up when at anchor. The cabin wall ends up having an uncomfortable and awkward protrusion on what would otherwise form a perfect back rest to lean against while one's legs stretch out sternwards.

Moore & Sons

Moore & Sons

Moore's boats abandon the Reecraft method and fit a winch on the cockpit combing, resiting the jam cleat just aft of it.

Given that it appears rare to find a boat with this simple combination, it seems that most owners find this arrangement unsatisfactory, perhaps because the cleat is not aligned well with the winch. The majority of boats have additional gear fitted for managing the genoa.

Pyecraft

Pyecraft

In its turn Pyecraft abandon the Moores winch, suggesting they did not offer a genoa. Photographs of Pyefleet boats and the position of the only cabin-top fairlead, set a little further aft and out than those on the earlier boats appear to confirm that their standard head sail was a 120% jib.

While this design does solve the Reedcraft "backrest problem" when at anchor, it cannot offer the same benefits when under sail.

The Main Sheet

The Main Sheet

Reedcraft

Reedcraft

The cockpit of most, if not all, Reedcraft boats were supplied with a pair of eyes mounted above and aft of the lockers to allow a four-point mainsheet system. Some boats were also fitted with a grooved slot jam cleat forward of the starboard eye.

On the typical boat the sheet is secured to the port cockpit eye then passes up to the double block on the boom, down to the transom and round another block before returning to the second pulley on the boom block before, finally, descending to the starboard eye, where it is taken round a second single block.

In the photograph above the sheet has been secured in the cleat a little forward of the starboard eye.

Moore & Sons

Moore & Sons

Moore's boats abandon the four point sheet and use only a central eye on the transom. There also appear to have been variations in the fittings supplied.

In the first version, the line is secured to the transom pulley and then passes up to the boom where it is taken round the smaller of two pulleys in the block. It returns the the transom where it passes round the pulley to ascend again to the boom. At the boom it rounds the larger pulley and on to the helmsman.

Some Moore's boats were supplied with a double block that included a jamming cleat. In this case the arrangement is inverted, with the single block and anchorage for the sheet attached to the boom and the double block secured to the transom.

Standing Rigging

Standing Rigging

Forestay

and shroud lines join the mast about a quarter of the way from the

peak, running via swept-back spreaders, to chainplates mounted on

the cabin sides slightly aft of the mast. Secondary shrouds lead to

the same anchorage point, from just under half way up the mast.

Forestay

and shroud lines join the mast about a quarter of the way from the

peak, running via swept-back spreaders, to chainplates mounted on

the cabin sides slightly aft of the mast. Secondary shrouds lead to

the same anchorage point, from just under half way up the mast.

Jeckells, the sailmakers who supplied the Dyneema cord seen here, suggested that three turns of this line produce a fixing that is both strong and subject to less stretching that the steel of the shroud line itself.

The trouble with attempting to fit bottle screws, which many current owners prefer, is that the connectors at each end often do not have the flexibility that permits each line its correct alignment. (A number of retro-fitted options found on owners boats is discussed in the Owners section of the site.)

There is no aft stay. Broads sailors welcome this. The business of lowering and raising the mast in order to pass under the many bridges becomes a much less risky affair, as there is one less rope to foul the outboard motor or get caught on the aft cleats!